Heat Press Setting For 65 Polyester 35 Cotton Vinyl

When it comes to heat printing polyester there are definitely challenges.

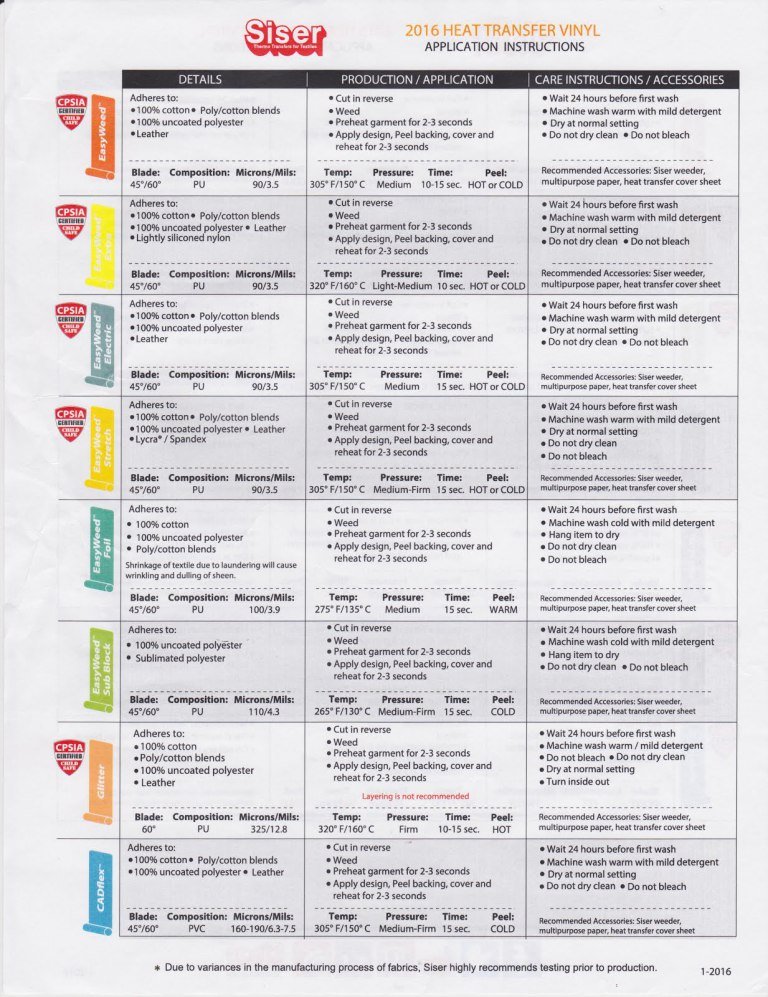

Heat press setting for 65 polyester 35 cotton vinyl. Since the rise of active wear and the popularity of athleisure apparel becoming a fashion trend the need for decorators to find the best methods for printing custom designs onto polyester fabric. In general terms somewhere between 270 and 300 degrees is likely to be ideal. If you d like the picture you re printing to look faded or old you can use these settings to achieve that. Once everything is set apply the glitter vinyl to the apparel using medium pressure and with a heat range of 300 to 320 f for around 15 to 20 seconds.

In addition you won t want to keep the heat applies for too long. 350 f for 10 seconds. The fabric seems difficult to decorate compared to the favorite cotton t shirt. If so what temperature and time is needed using the heat press.

I was wondering if i can use easy weed on this. Heat press temp for antique look. Heat press temp for cotton. Allow your iron to preheat for no less than five minutes.

Plug your iron into an electric outlet and set it to the highest setting for cotton polyester blends. Lily july 10. Peel carrier hot or cold. You can use glitter vinyl with polyester cotton and other fabrics.

Set iron dial between cotton and linen cover design with heat transfer cover sheet or multipurpose paper place on flat hard surface ironing board not recommended press iron with medium firm pressure for 10 15 seconds if areas of design lift after application replace cover sheet and re press for 5 10 seconds. Set your iron to cotton and press for 20 30 seconds. Set your iron on the hottest setting the cotton and polyester blend will take. 65 polyester and 35 viscose.

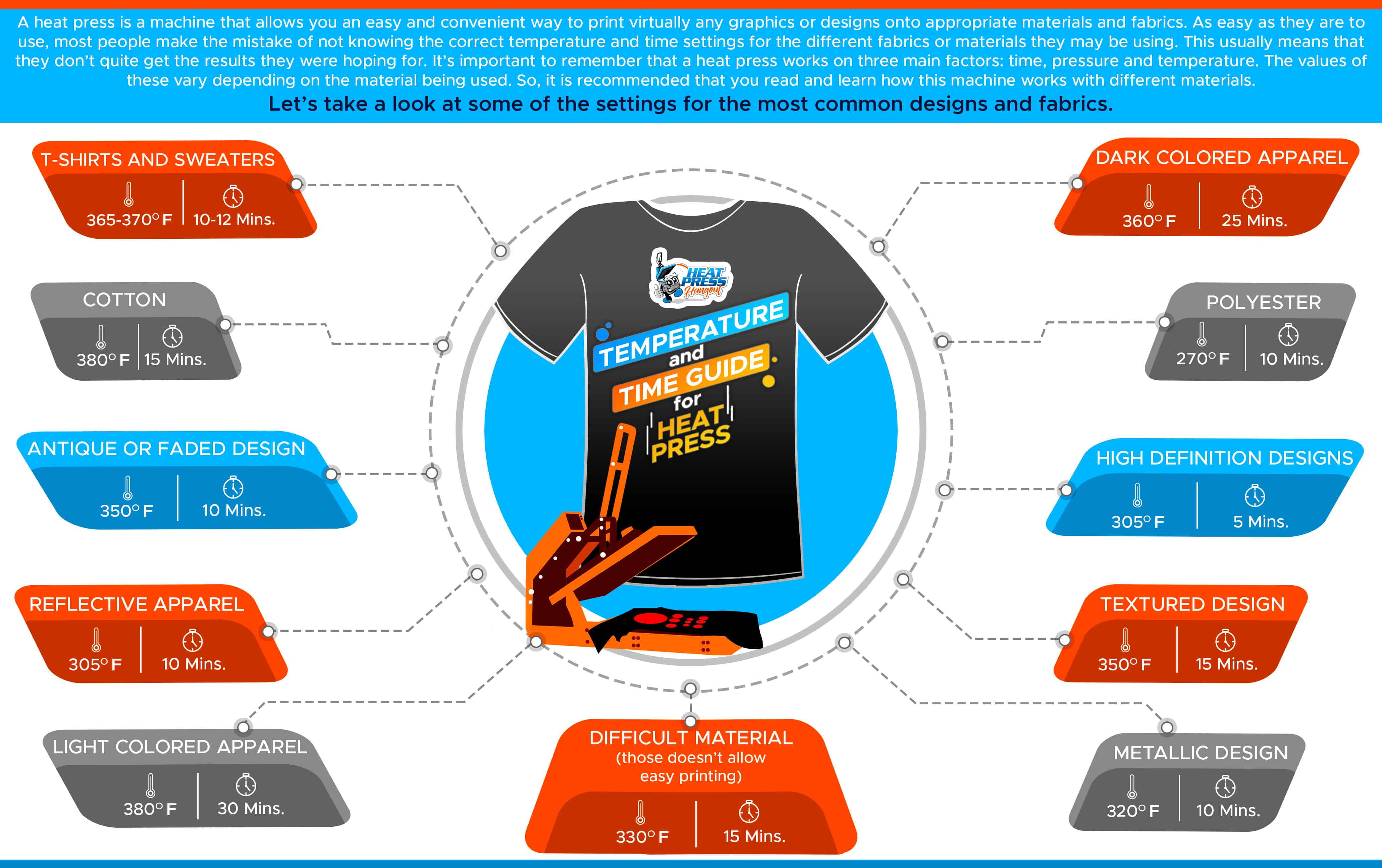

While you can safely apply heat transfer vinyl to polyester and cotton safely other materials may introduce variables that can cause issues particularly with darker color garments. Heat press temperature chart the ultimate guidea heat press machine has three basic principles that enable you to print your artwork on garments. Step 5 cut the image from the transfer sheet and center it face down on the fabric. Set your heat press to 280 f.

If using a commercial press heat to 375 fahrenheit 190 celsius and skip to step 3. Heat pressing at 380 f for 15 seconds would deliver great results. If any htv lifts as you peel the carrier lay it back down and press for another 10 seconds. You must be aware of the settings needed for the time pressure and temperature to get the best performance.

The three aspects need to be synchronized to their accurate values before. Tri blends are very popular which often have a composition of 50 polyester 25 cotton and 25 rayon but the composition could vary of course. If you want to heat press polyester then it is best to stick to a slightly lower temperature than you would use on more heat resistant fabrics such as cotton.